| Product Code | Description | Product Size | Form | Storage Temperature |

| 901090-25G | Silver nanoparticles ink for screen printing | 25g | Viscous liquid (paste) | 2-8°C |

Silver nanoparticles ink for screen printing, low curing temperature – Sigma-Aldrich

RM1,781.00

Brand:

Sigma-Aldrich

Synonyms

Ag ink, Conductive ink, SmartâInk S-CS21303 conductive ink

Cas No.

–

General description

Product benefits:

- Very high electrical conductivity.

- Very low curing temperature for printing on flexible substrates.

- Non CMR ink.

- Unchanged conductivity on bending.

- Compatible with various curing processes including photonic, IR, low vacuum oven and thermal.

- Good adhesion on various flexible substrates (PET, Kapton®, â¦).

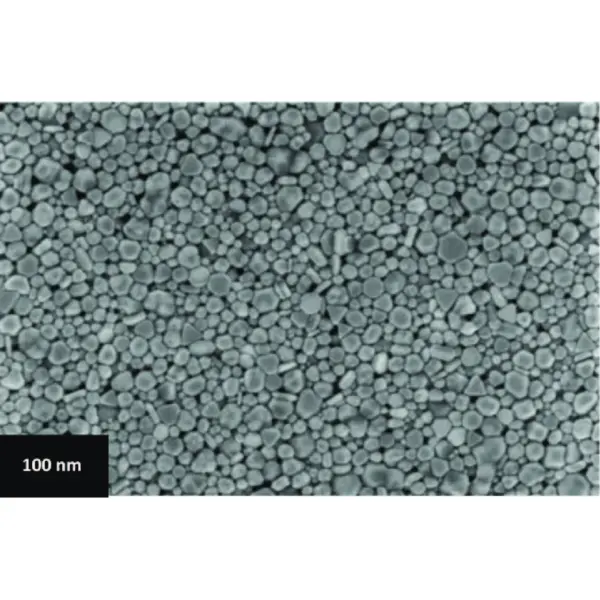

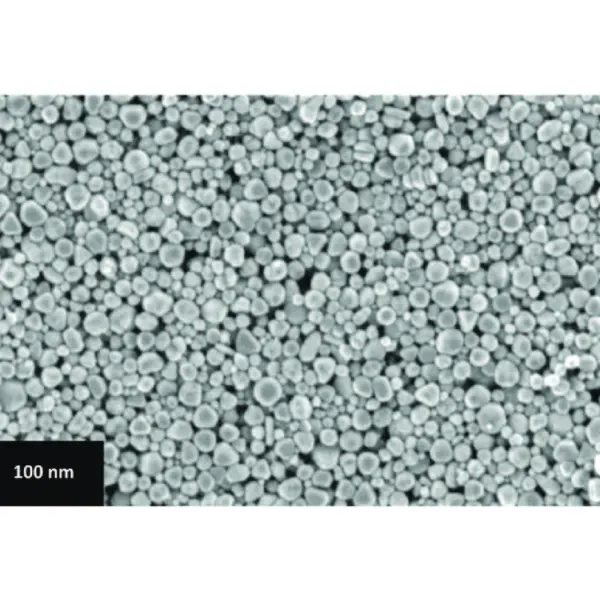

Smartâ²Ink S-CS21303 conductive ink developed for printed electronics market is particularly well suited for applications requiring high conductivity and high resolution at very low curing temperatures. This ink, based on silver, is perfectly adapted to design conductive tracks on flexible substrates and is suitable to produce antennas for IoT applications (HF, UHF).

This ink has been developed to address the applications which require very low curing temperatures.

Preparation Note

Typical processing guideline:

- Smartâ²Ink S-CS21303 conductive ink needs to be agitated before use.

- Ready to use. No need to use thinner.

Other Notes

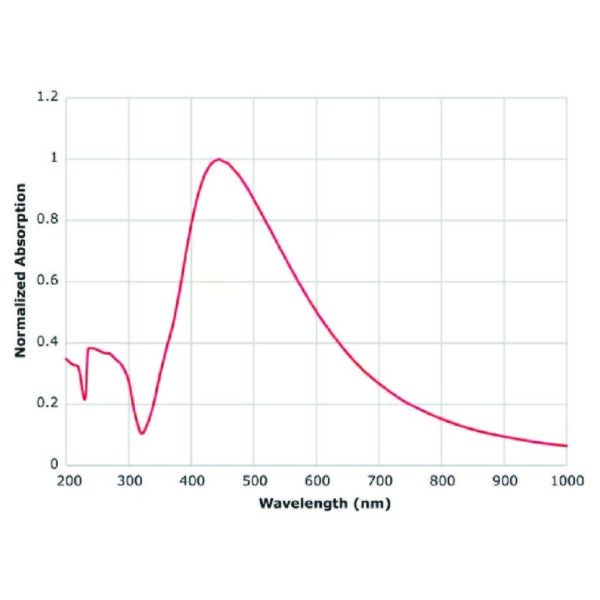

Resistivity: â¤1 mΩ/sq, per 25 μm (screen printed on PET, curing at 200 °C/5 min)

â¤3 mΩ/sq, per 25 μm (screen printed on PET, curing at 120 °C/5 min)

â¤4 mΩ/sq, per 25 μm (screen printed on PET, curing at 80 °C/5 min)

â¤5 mΩ/sq, per 25 μm (screen printed on PET, curing at 60 °C/5 min)

Legal Information

Product of Genesâ²Ink

Kapton is a registered trademark of E. I. du Pont de Nemours and Company

| Dimensions | 30 × 60 cm |

|---|---|

| Brand | Sigma |

| Estimated Delivery Time | 3-6 weeks |